Inspection and certification

We approve all brands and types of hoists

Available 24/7 worldwide for inspections

Total solution for rigging equipment rental

Highly experienced technical staff

Worldwide approval

It is mandatory to have your engine hoists inspected annually, regardless of where you got them from and what you use them for. Rigging Box may and can inspect any type of engine hoist of any brand and provide it with a rigging certificate. We do this anywhere in the world. We understand that your engine hoists are sometimes on the road for more than a year, for example as part of a tour. It is therefore no problem for us to carry out the inspection abroad.

Inspection of Chain Hoists

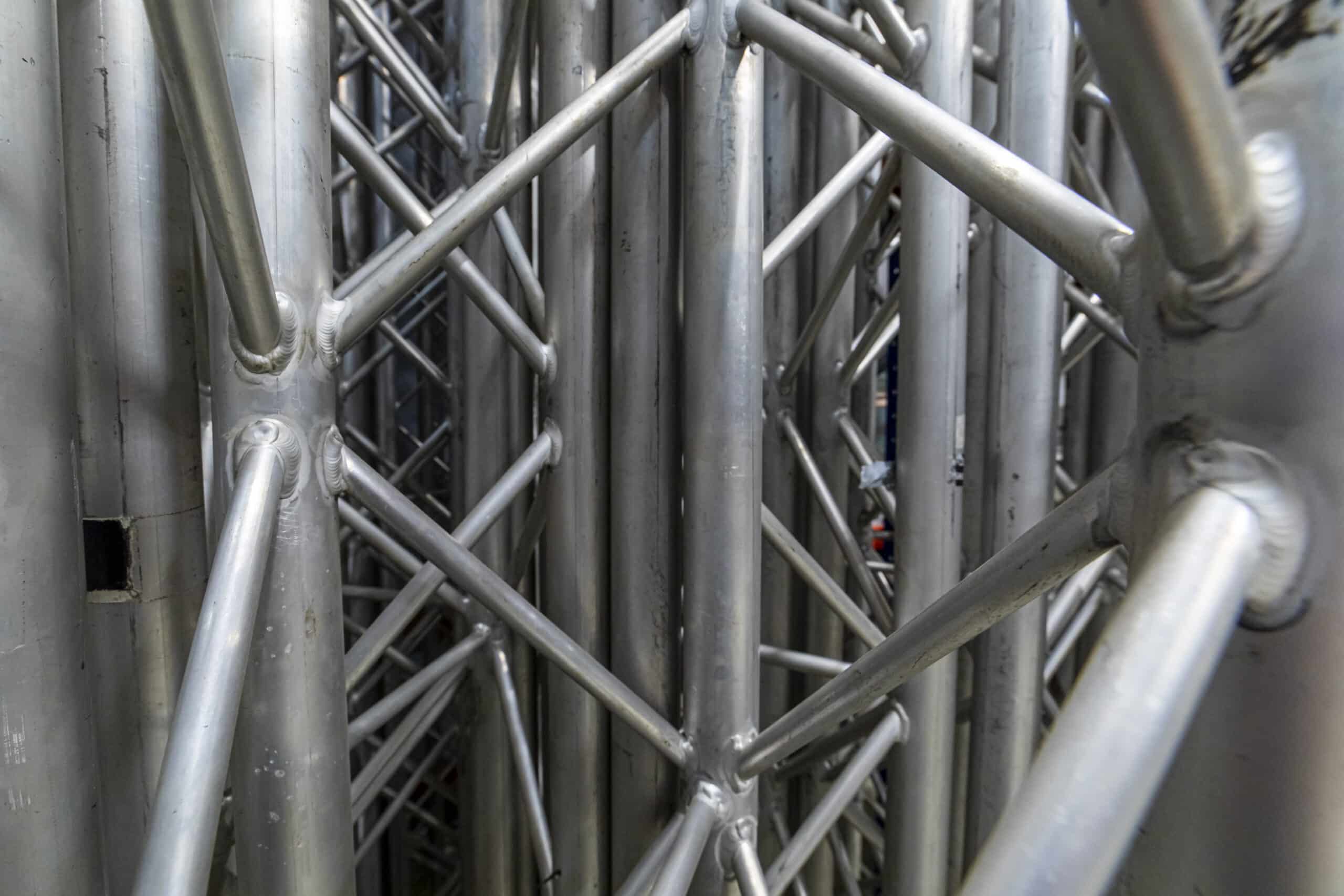

Inspection for trusses

Of course, our trusses are also regularly checked and certified. You can always assume that the trusses you rent from us are safe and reliable. At the moment, all trusses per category are provided with a rigging certificate. In the future, we will switch to a system in which each individual truss is provided with a QR code. This makes it easy to trace the inspection history per truss.

The inspection process

Contact with Rigging box

Are you already a customer? Then you will receive an annual reminder for the inspection and you can then schedule an appointment. Is this your first inspection via Rigging Box? Then we will first come to your location to inventory the situation. We will then see whether an inspection is useful at all and whether the materials are sufficiently accessible.

The inspection itself

We make an appointment and come to your location to check the material according to our own guidelines and methodology. We inspect both the material itself and the installation. For example, if we see that something has been hung incorrectly, we will advise you on the correct method. We also take photos for the report.

Further steps

Do we find something broken during the inspection? If possible, we will repair it on site, if not, we will take it to our workshop. If necessary, we will order new parts and carry out the repair. In some cases, it is more advantageous to rent new equipment. This is always done in consultation with you.

Certification

Based on our findings and inspection, we draw up the certificates. We send these certificates by e-mail and also place them in HoistBox, our own online environment. If repairs have been carried out, we indicate this on the rigging certificate. This way, you can always view the repair history of your equipment.

Contact Us

"*" indicates required fields